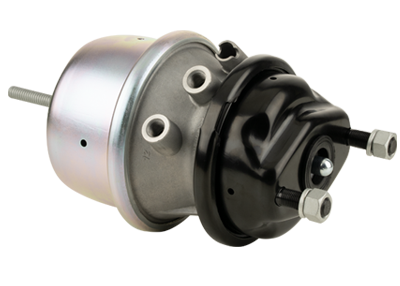

An air disc brake chamber is a component of an air brake system used in vehicles such as trucks and buses. It is a cylindrical device that houses the brake actuator, which is the mechanism that pushes the brake pads against the brake rotors to slow or stop the vehicle. The air disc brake chamber is typically mounted on the back of the brake caliper, and it receives pressurized air from the air brake system to activate the brake actuator. When the driver applies the brakes, pressurized air is sent to the brake chamber, which in turn pushes the brake actuator and applies the brakes.

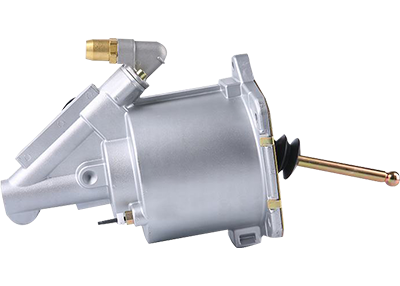

The air disc brake chamber is a crucial component in the braking system of heavy-duty commercial vehicles, such as trucks and buses. Its primary function is to convert the energy of compressed air into mechanical force, which is then used to activate the brake calipers that clamp down on the brake rotor.

The air disc brake chamber consists of two chambers: the diaphragm chamber and the push rod chamber. When the brakes are applied, the compressed air enters the diaphragm chamber, causing the diaphragm to move and push the push rod. The push rod then applies force to the brake caliper, causing it to press the brake pads against the brake rotor and slow down or stop the vehicle.

The air disc brake chamber is designed to be highly reliable and durable, as it is subjected to constant use and heavy loads. It is also designed to withstand extreme temperature variations, vibrations, and other harsh operating conditions.

Proper maintenance and inspection of the air disc brake chamber are essential to ensure its optimal performance and prevent brake system failures, which can lead to accidents and other serious consequences.

The air disc brake chamber is a standard component in heavy-duty commercial vehicles equipped with air disc brakes. The air disc brake chamber is designed to be highly reliable and durable, capable of withstanding constant use, heavy loads, and harsh operating conditions.

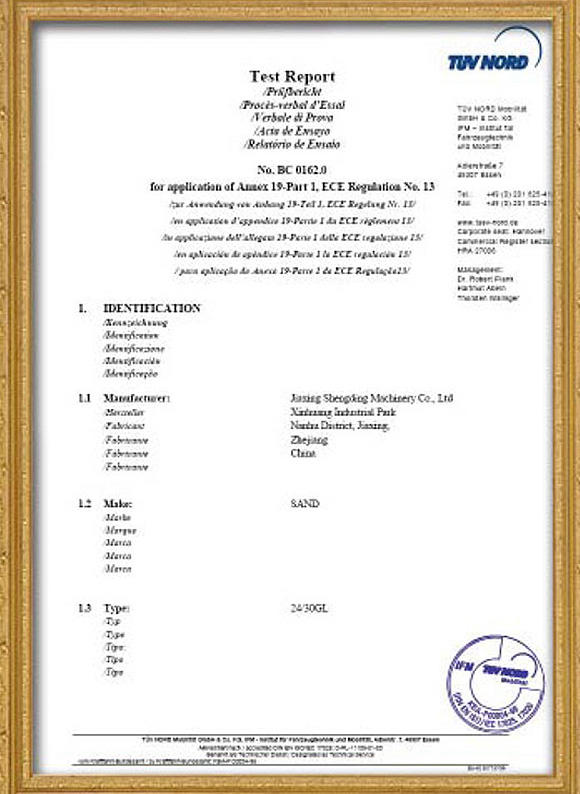

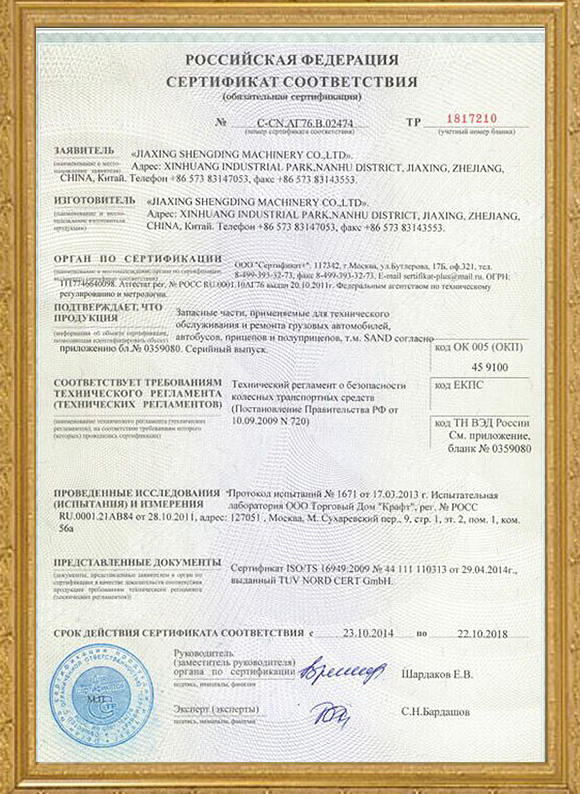

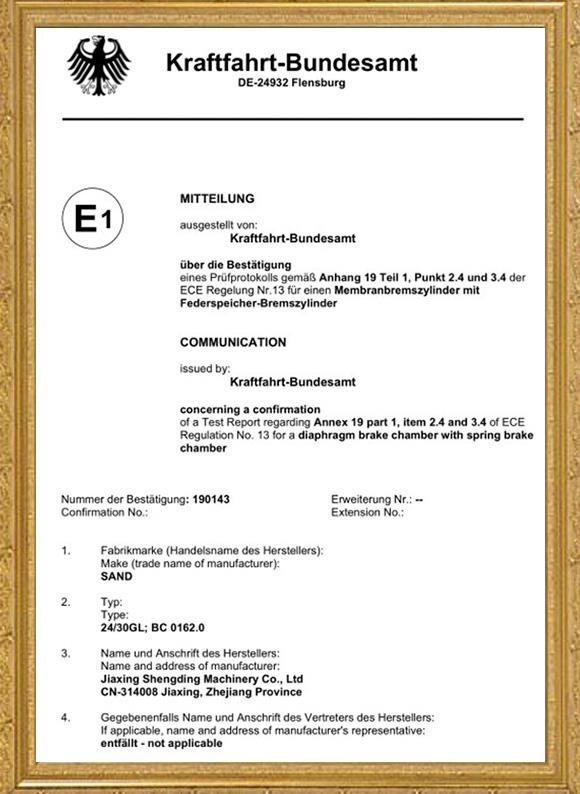

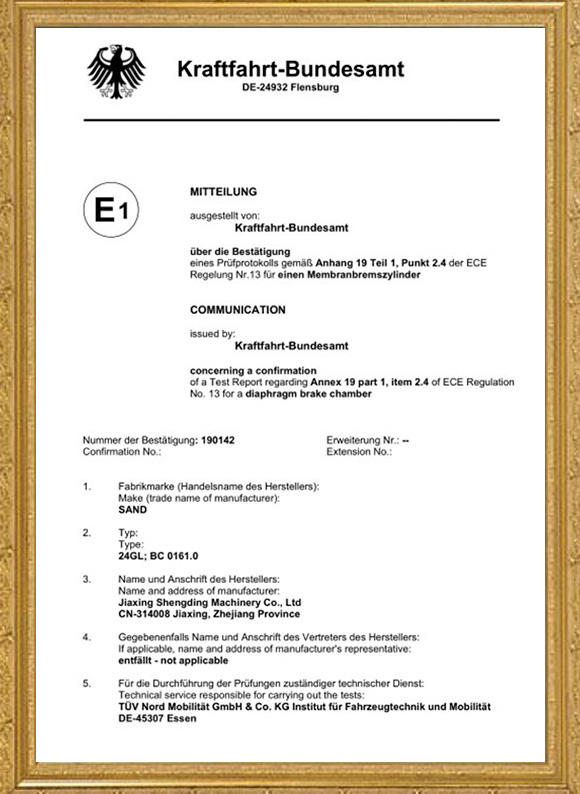

In terms of standards, the air disc brake chamber must comply with various regulations and industry standards, such as the Federal Motor Carrier Safety Administration (FMCSA) standards, the Commercial Vehicle Safety Alliance (CVSA) guidelines, and the Society of Automotive Engineers (SAE) standards.

The air disc brake chamber is primarily used in the braking system of heavy-duty commercial vehicles such as trucks and buses. These vehicles are equipped with air disc brakes, which provide better stopping power and more consistent braking performance than traditional drum brakes. Air disc brakes are also easier to maintain and repair, and they generate less heat, which helps to extend the life of the brake components.

The air disc brake chamber is an essential component in the air disc brake system, as it is responsible for converting the energy of compressed air into mechanical force that activates the brake calipers. Proper maintenance and inspection of the air disc brake chamber are critical to ensure the safe operation of the vehicle and prevent brake system failures, which can lead to accidents and other serious consequences.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语