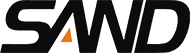

A spring brake cylinder (also known as a DD3 safety chamber) is found on the rear axle of most heavy trucks. It is used for parking and emergency braking in case the service brakes fail. The system works by supplying air to one side of a diaphragm inside the brake chamber and applying it to the other side. That then pushes a rod that applies the brake shoes to the drum or disc and slows down the truck.

The large coil spring inside the brake cylinder is under high tension, which could cause hazardous damage if it is accidentally released. This is why the braking system is designed to release only when the air pressure in the entire air brake system drops below a specified level – normally about 414 kPa or 60 psi.

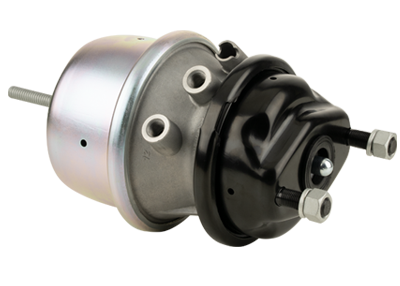

To prevent the accidental release of the spring brake, a special type of control valve is installed on most vehicles that are fitted with this system. It is a push/pull type valve fitted with a yellow, four-sided knob located near the driver. It is pushed to supply air and release the spring brakes, then pulled to exhaust the air and apply the brakes.

When the vehicle is parked, the control valve is usually set to the “off" position. In the event that the air pressure in the entire braking system drops below the specified minimum, the valve will automatically start to supply the air to the spring brakes, which causes them to apply and slow the vehicle. The air pressure that is needed to hold the spring brakes applied is supplied by a separate, round blue control valve on some tractors and trailers that is used for spring brake applications only.

In order to release the spring brakes, the driver must first operate the control valve and then press the brake pedal for three to five seconds. During this time, air pressure is applied to the power spring on the front of the brake cylinder. This forces the diaphragm in the rear of the cylinder to compress and apply the brake shoes on the rear wheels. When the brake is released, the pressure in the cylinder returns to normal and the shoes are released. The vehicle may then be driven, but it is important to remember that the spring brakes do not have the braking power of the full service brake application. They are only intended to provide a safe and controlled stopping distance in an emergency situation. This system was originally developed for safety reasons to ensure that trucks could be stopped and backed up in the event that the service brakes were lost. It is now a common feature in all types of commercial vehicles. The safety of the spring brakes is enhanced with a cage bolt, which protects the spring from being accidentally released. When the driver is ready to move the vehicle, this bolt can be accessed through a hole in the side of the cylinder and manually compressed by turning it with a hex tool.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语