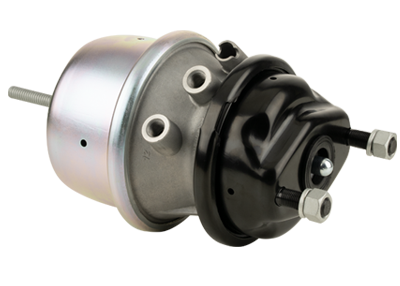

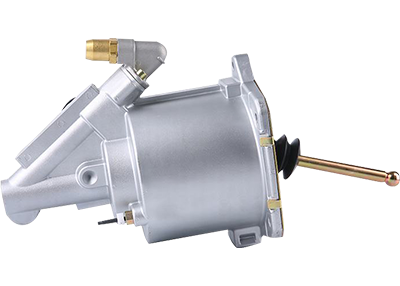

The construction of a disc brake chamber involves the use of various materials to ensure durability, reliability, and proper functioning. The specific materials can vary between different manufacturers and models, but here are common materials used in the construction of disc brake chambers:

Aluminum Alloy:

Purpose: Aluminum is often used in the construction of disc brake chambers due to its lightweight nature and corrosion resistance.

Advantages: Aluminum alloys provide strength and durability without adding excessive weight to the braking system.

Stainless Steel:

Purpose: Stainless steel is employed for specific components within the disc brake chamber.

Advantages: Stainless steel offers excellent corrosion resistance and durability, making it suitable for parts exposed to the elements.

Cast Iron:

Purpose: Some disc brake chambers may incorporate cast iron components.

Advantages: Cast iron provides high strength and durability, contributing to the overall robustness of the brake chamber.

Steel Alloys:

Purpose: Various steel alloys, such as carbon steel, may be used in the construction of certain components.

Advantages: Steel alloys offer strength and toughness, ensuring the components can withstand the forces and pressures associated with braking.

Rubber and Polymer Components:

Purpose: Seals, gaskets, and other components within the disc brake chamber may be made from rubber or high-quality polymer materials.

Advantages: Rubber and polymer components contribute to the sealing properties of the chamber, preventing contaminants from entering and maintaining airtight integrity.

Plastic Components:

Purpose: Some non-structural components may be made of durable plastics.

Advantages: Plastic components can reduce overall weight and contribute to the corrosion resistance of the brake chamber.

Surface Coatings:

Purpose: Protective coatings, such as zinc plating or other anti-corrosion treatments, may be applied to metal surfaces.

Advantages: These coatings enhance resistance to corrosion and improve the longevity of the brake chamber.

Aluminum Bronze:

Purpose: In certain applications, aluminum bronze may be used for its corrosion resistance and wear resistance.

Advantages: Aluminum bronze provides strength and durability in challenging environments.

It's important to note that the specific materials used can depend on the manufacturer's design choices, the intended application of the disc brake chamber, and compliance with industry standards. When choosing a disc brake chamber, it's recommended to refer to the product specifications provided by the manufacturer to understand the materials used and their benefits in terms of performance and longevity.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语