Regular Inspections:

Perform routine visual inspections of the air brake actuator, looking for signs of damage, wear, or leaks.

Check for any oil, moisture, or contaminants around the actuator, which could indicate an air leak or malfunction.

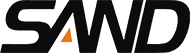

Diaphragm Inspection:

Inspect the diaphragm for signs of cracks, tears, or distortion. A damaged diaphragm can affect the actuator's performance and brake engagement.

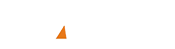

Push Rod and Linkage:

Check the push rod and linkage for proper alignment, wear, and damage. Ensure that they move freely and are not binding.

Air Lines and Fittings:

Inspect air lines, connectors, and fittings for leaks, cracks, or damage. Leaks in the air lines can lead to reduced brake pressure and compromised braking performance.

Brake Shoe Adjustment:

If applicable, check the brake shoe adjustment to ensure proper clearance between the shoes and the drum or rotor. Improper adjustment can lead to uneven braking and excessive wear.

Lubrication:

Apply appropriate lubrication to moving parts, such as the push rod and linkage, to ensure smooth operation and reduce wear.

Air Chamber Inspection:

Check the air chamber for signs of damage or leaks. Ensure that the air chamber is securely attached and functioning properly.

Seal and Gasket Inspection:

Inspect seals and gaskets for signs of wear, cracks, or deterioration. Damaged seals can lead to air leaks and reduced braking efficiency.

Electronically Controlled Systems:

If the air brake system is electronically controlled, ensure that sensors, connectors, and wiring are in good condition. Test the electronic components for proper operation.

System Bleeding:

Regularly bleed the air brake system to remove any air pockets, which can affect braking performance.

Documentation:

Maintain records of inspections, maintenance, and repairs performed on the air brake actuators. This documentation can help track the history of the system's maintenance and identify any recurring issues.

Manufacturer's Recommendations:

Follow the manufacturer's guidelines and maintenance schedules provided in the vehicle or equipment manual. These recommendations are tailored to the specific components and system in use.

It's important to note that maintenance practices may vary depending on the type of vehicle, equipment, and air brake system being used. Regular and proactive maintenance is crucial to ensure the safety of the vehicle, the operator, and others on the road. If any issues or abnormalities are detected during inspections, it's recommended to address them promptly and seek professional assistance if needed.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语