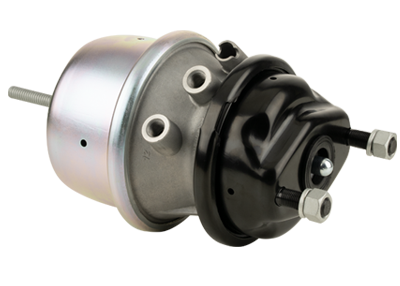

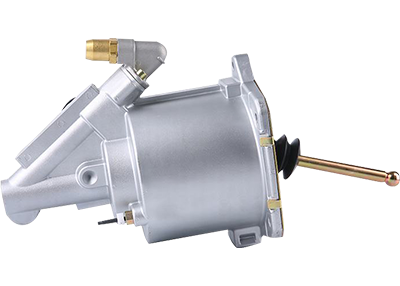

Spring brake cylinders are an essential component of air brake systems in heavy-duty vehicles. They are designed to provide a safe and reliable parking brake function in the event of air pressure loss. Some common problems with spring brake cylinders include:

Air leaks: Air leaks can occur due to damaged seals, gaskets, or diaphragms.

Broken springs: Broken springs can cause the brakes to fail or not release properly.

Corroded components: Corrosion can cause the internal components of the spring brake cylinder to become damaged or fail 1.

Diaphragm damage: The diaphragm in the spring brake cylinder can become damaged, torn, or punctured, causing air pressure loss and brake failure. Diaphragm damage can result from age, wear, or debris intrusion.

Spring brake failure: If the spring brake cylinder fails to apply or release the spring brakes as intended, it can lead to the vehicle's inability to move or stop, posing a significant safety risk.

Inoperative parking brake: Spring brake cylinders are responsible for applying the parking brake when the air pressure drops or fails. If the cylinder is faulty, it can prevent the parking brake from engaging or disengaging correctly.

Overheating: In some cases, excessive heat generated during braking can affect the spring brake cylinder's performance. Overheating can lead to deformation or damage of critical components.

Stuck or frozen components: Cold weather can cause the internal components of the spring brake cylinder to freeze, leading to a failure to apply or release the spring brakes. Proper winterization and maintenance are essential to prevent this issue.

Contamination: Dust, dirt, or other contaminants can enter the cylinder's interior, causing damage to seals and diaphragms and potentially leading to air leaks or reduced performance.

Spring break imbalance: If one side of the spring brake cylinder operates differently from the other, it can result in uneven braking, leading to control and stability issues when stopping the vehicle.

Mounting and alignment problems: Improper installation or alignment of the spring brake cylinder can affect its performance and lead to issues with brake engagement and release.

Wear and tear: Over time, the components of a spring brake cylinder can wear out, including seals, diaphragms, and springs. Regular inspection and maintenance are necessary to replace worn components before they lead to more significant problems.

If you are experiencing any of these issues, it is important to have your vehicle inspected by a qualified mechanic as soon as possible to prevent further damage and ensure your safety on the road.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语