The diaphragm, a reusable, dome-shaped cup that fits over the cervix, and spermicide, a gel that blocks sperm from fertilizing an egg, are now being used by up to 17 percent of women in the United States. It is a safe, effective form of birth control that can prevent pregnancy in 85 out of 100 cases. But to work, the diaphragm must be perfectly fitted, and inserted up to six hours before sexual intercourse.

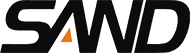

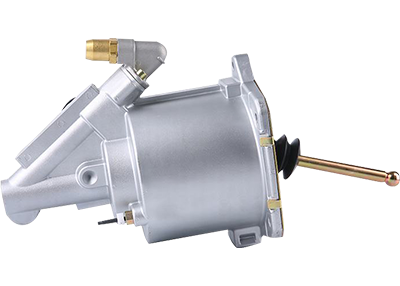

The air-operated diaphragm brake 2 comprises a service brake chamber 12 and a spring brake chamber 14 joined in tandem. A double-cup-shaped service/spring adapter housing 18 is fastened to the service brake chamber by a clamp 20.

The adapter push-rod extends through an aperture in the service brake actuator. Dust shields are positioned to prevent contaminants from entering the service brake chamber.

These include a compact design that reduces overall engine height, and less friction from fewer moving parts. But there are some disadvantages that come with a pushrod engine, including a limitation at high RPMs caused by valvetrain inertia and larger reciprocating masses.

Inside the brake chamber are two concave metal halves held together by a clamp, and a rubber diaphragm sandwiched between them. A threaded pushrod extends from one end of the chamber to a clevis that’s attached to the brake line. The length of the clevis determines how far the pushrod will travel when compressed air from the brake pedal is applied. An incorrectly adjusted clevis length will decrease brake efficiency and cause brake lag.

Brake Pedal

The brake pedal is a class-two lever that lets you use air pressure to control your brakes. Air flows through the brake chamber and nozzle and when you push on the pedal, the air pressure moves an "S-Cam" to force the brake shoe linings apart from each other against the brake drum. This creates friction and slows the wheel down.

When you stop the vehicle and take your foot off of the brake pedal, the air pressure in the brake chamber decreases, allowing the brake shoes to spread apart and come into contact with the drum again. A stiff return spring then causes the brake shoes to move back into their original position.

A spongy brake pedal is usually caused by hydraulic problems and not mechanical ones. However, a new master cylinder that is defective can make the brake pedal feel soft. This is rare, but it does happen. Repeated pumping of the brakes can usually restore enough pressure to stop your truck.

Air brake chambers convert air pressure into mechanical push rod force that engages the foundation brake shoes of your truck’s foundation system. This makes them a critical component in the overall foundation braking system.

Audible air leaks around the chamber; missing parts like dust plugs, caging bolts, or clamp bands; and visual damage to the chamber are all common signs that it’s time for a new one. These problems allow water and debris to enter the park side of the chamber, causing corrosion on the power spring or power piston and ultimately leading to failure.

When installing a replacement, make sure it’s the same size as the original chamber to ensure parking/emergency brake forces are balanced on each axle. Air brake chambers from different manufacturers may look similar, but the mounting holes are sized differently. This changes the effective length of the slack adjuster and affects braking performance. The slack adjuster’s effective length is also affected by the position of the pushrod in the applied position, and should be set at the same level on each end of the axle.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语