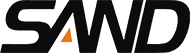

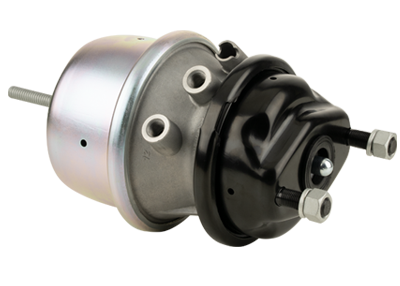

It is a reliable parking brake and acts as an emergency brake in the event of air-pressure loss elsewhere in the system . The spring-brake chamber also serves as a service-brake section on a front tandem axle that works in the same way as a separate service-brake chamber.

The large coil spring inside a spring-brake chamber is under high tension and can be dangerous to work with. Tampering, corrosion or damage to the spring can cause it to release, resulting in sudden, violent movement of parts within the cylinder.

When there is a problem with a spring-brake chamber, such as a leaking seal or a broken hose, technicians may use a manual caging method to compress or "cage" the spring, temporarily disabling it from applying. This is done by using a cage bolt that can be tightened to decompress the spring.

This allows the technician to move the vehicle to a safe location without risk of moving it in an unsafe manner. The cylinder is then reset and air pressure in the system can be restored.

Most trucks, buses and tractors are fitted with a spring-type parking-brake system. These are connected to the service-brake chambers and operate through the same linkage, so the effectiveness of these brakes depends on the adjustment of the service-brake chambers.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语