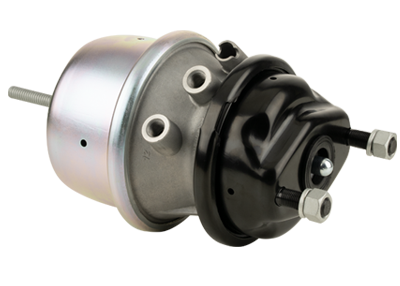

Wedge brakes are another type of air drum brake found on some heavy trucks. They use a push rod that directly contacts the brake shoes and drum, pushing the brake shoe linings against the drum. Unlike cam brakes, wedge brakes have no exposed brake linkage and don’t require frequent manual adjustment.

These brakes are also known as “S-cam” or “cam and wedge” brakes, and they are often used on military vehicles. Like the other types of foundation brakes, they include an air brake chamber, brake shoes and linings, camshafts, pushrods, spiders, return springs, dust shields and brake adjusting screws or bolts.

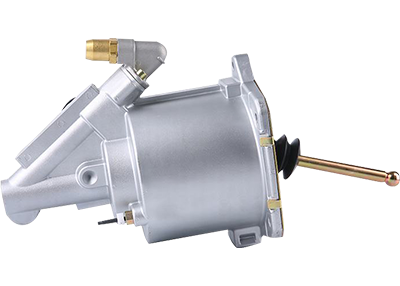

The brake adjusting bolt is usually located under the slack adjuster arm of the air brake. It is important to make sure that the slack adjuster arm does not move away from the brake chamber when turning the adjusting bolt. If this is happening, it means that the slack adjuster is not properly adjusted.

An improperly positioned slack adjuster can result in uneven brake actuation, which can cause a loss of stopping power and damage the brake caliper or rotor. This can be dangerous for the truck driver and passengers.

To check if the slack adjuster is in proper adjustment, make a full brake application and measure the amount of free stroke (the distance between the mark made with a piece of chalk on the slack adjuster arm and the face of the air brake chamber) using a calibrated ruler. Typically, a free stroke of 1/2 to 3/4 of an inch is ideal for a standard type 30 brake chamber. If the slack adjuster has more than this amount of free stroke, it needs to be adjusted.

Another common myth is that an air brake adjustment can be checked from the cab by making a full brake application and watching for a pressure drop of 8-12 psi on the truck’s reservoir gauge. This method is dangerous because it relies on a large air pressure change to detect a small change in the slack adjuster position. Modern truck reservoirs have very large capacity, so even a slight difference in the slack adjuster position can result in a very substantial pressure change that could be difficult to detect on a standard gauge. Additionally, most truck reservoir gauges have fine markings that are not large enough to accurately determine this change in pressure.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语