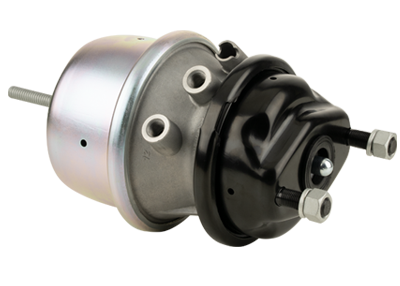

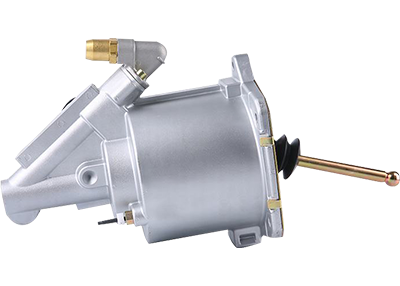

Wedge brakes use leverage to multiply the force of an air chamber by pushing a wedge-shaped push rod between two brake shoe rollers, forcing the braking linings against a brake drum. The resulting friction slows the vehicle and stops it, and a wedge-shaped push rod helps to prevent brake lining wear by pushing both brake shoes together when the brakes are not applied.

There are three main types of foundation brakes found on commercial trucks – S cam brakes, wedge brakes and disc brakes. S cam brakes are the most common type of foundation brake found on trucks today, utilizing air pressure proportional to brake pedal travel to push air through an actuator chamber and force brake shoes against the surface of a brake drum. The cams on S cam brakes rotate to energize the primary brake shoes by moving them up against the brake drum, and to disengage them when applying the brakes.

Cam brakes are usually self-adjusting and don’t require regular maintenance or adjustment. However, if the primary brake shoes are worn too much or the brake drum is damaged, then the cams may need to be manually adjusted using an adjusting wrench called a star wheel adjuster. This is a job typically performed by a truck mechanic, since this wrench must be removed from the cab to access the adjusting bolt and shims underneath the brake assembly.

The adjustment process requires you to measure the length of the brake’s slack adjuster arm, or the distance between a fixed reference point at the brake chamber and the end of the pushrod. You also need to compare the measured pushrod stroke with the air brake chamber’s adjustment limit, which is generally marked on the pushrod or specified in the manual for the specific truck.

The first step is to remove the dust cover from adjusting slots at two places on each brake, one in front of the forward brake chamber and above the rear brake chamber on single-chamber units. The adjusting bolts are right-hand threaded and can be turned to reduce the slack in the shoe and increase the brake’s angular movement against the brake drum. If you are unable to turn the adjusting bolt to a point where there is a heavy drag on the brake, then the star wheel adjustment has been incorrectly set and should be corrected with the brake jacked up. The same method should be used to inspect the primary and secondary shoe-to-drum friction on each brake.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语