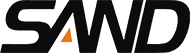

A spring brake cylinder is a component that helps to build pressure on a brake fluid. It is also known as a pressurizing chamber. It is mounted underneath the reservoir and connected to it with an intake port and compensating port.

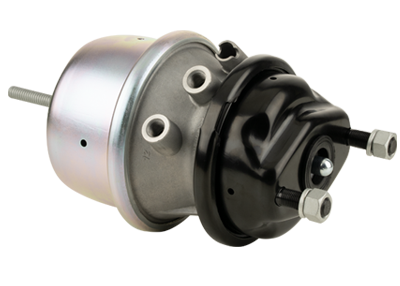

The cylinder has a primary seal that allows the brake fluid to flow into the cylinder during depressing of the brake pedal. The secondary seal keeps the pressure in the cylinder after the pedal is released.

The cylinder also has a piston that is driven by a pushrod. When the brakes are actuated, the pushrod moves inside and forces the piston up against the return spring. The cylinder then pumps the brake fluid into the brake lines at high pressure. It also has a check valve and compensation port. This enables the cylinder to build up a maximum of pressure in the event of the brake fluid reservoir losing its air pressure. The cylinder also stores the excessive brake fluid in its reservoir.

A spring brake cylinder consists of a piston seal, a piston rod and a compression spring. The brake pedal feel of a vehicle is determined by the performance of these components. A spongy, low or falling pedal indicates that the master brake cylinder needs to be serviced or replaced.

Due to this arrangement, tilting of the hat-shaped piston 5 inside the housing of the spring brake cylinder and a resulting jamming thereof can be prevented. The radial distance between the two guide elements is essentially determined by the radial material thickness of the middle part of the piston and therefore advantageously low, while the axial guide length is comparatively large.

A spring brake cylinder has both a service and a parking (or emergency) brake chamber in one unit. The two sections are "piggy-backed" together and act the same as separate chambers, except that a large coil spring is added to the parking brake section. The spring, which is under high pressure, provides the fail-safe mechanism to stop a car in the event of air loss.

To release the spring and stop the car, the control valve must be pushed to supply air, and pulled to exhaust air and apply the spring brakes. This is normally a push/pull type valve fitted with a yellow, four-sided knob located near the driver.

When the spring brakes are engaged, blocks must be placed under the wheels of the vehicle to prevent roll-away and potential personal injury. All spring brakes have a way to mechanically release the coil spring tension, called a caging bolt. Before this can be turned, the service push rod must be cut and the caliper's slave piston must be removed.

Maintenance

The large coil spring used in the spring brake chamber is under high tension, so it's designed to be tough. However, tampering or damage to the spring can cause it to suddenly release, which could result in a violent loss of pressure in your rear wheels. This is not good for your truck or trailer, and it's a sure way to put yourself in danger!

To prevent this, always use air line fittings that are specifically rated and approved for use on your air brakes. Also, don't try to "reuse" tubing or hoses that have been previously connected to your service brake chamber. You'll need to have high-grade tubing that is specifically rated for airbrake use.

The power spring is subjected to a corrosive environment every time it's compressed. This is especially true if your vehicle spends months at a time sitting idle on the lot. A protective coating can help, but it's not as effective as preventing a corrosive environment from developing in the first place.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语