Inspecting and maintaining air brake chambers is essential to ensure the safety and reliability of the braking system in vehicles and machinery. Regular inspections and maintenance help detect issues early and prevent brake system failures. Here are the steps to inspect and maintain air brake chambers:

Note: Before performing any maintenance or inspections on air brake chambers, ensure that you are familiar with the specific procedures outlined in the manufacturer's service manual and that you follow all safety precautions. If you are not experienced in brake system maintenance, it's advisable to seek the assistance of a qualified technician.

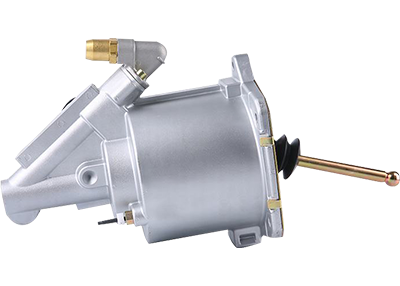

1. Visual Inspection:

Start with a visual inspection of the air brake chambers. Look for signs of damage, corrosion, or oil leaks. Pay attention to the condition of the diaphragm, pushrod, and return spring.

2. Air System Inspection:

Check for air leaks in the air brake system. Leaks can affect the performance of the brake chamber. Listen for hissing sounds or use a soap solution to identify leaks around fittings and connections.

Ensure that the air hoses and fittings are secure and not damaged.

3. Brake Adjustment:

Verify that the brake adjustment is within the recommended specifications. Proper brake adjustment ensures that the brakes engage and release as needed. You may need to check the brake chamber's pushrod travel and adjust it if necessary.

4. Diaphragm Inspection:

Inspect the diaphragm for any signs of wear, tears, or cracks. A damaged diaphragm can lead to air leaks and reduced brake performance. Replace the diaphragm if it is damaged.

5. Pushrod and Return Spring Inspection:

Check the pushrod for signs of wear or bending. Ensure that it moves freely and does not bind.

Inspect the return spring for damage or corrosion. Make sure it is properly positioned and functioning.

6. Mounting Hardware and Bolts:

Inspect the mounting plate, bolts, and fasteners that secure the air brake chamber to the vehicle or machinery. Tighten any loose bolts and replace damaged hardware.

7. Lubrication:

Apply a small amount of appropriate lubricant to moving parts like the pushrod to ensure smooth operation. Use a lubricant recommended by the manufacturer.

8. Dust Boots and Covers:

If your air brake chamber is equipped with dust boots or covers, make sure they are in good condition and free from debris. Replace damaged or missing boots or covers.

9. Brake System Testing:

Conduct a brake system test to ensure that the brakes engage and release as they should. This may involve applying and releasing the brakes and checking for proper operation.

10. Record Keeping:

- Maintain a maintenance log that includes inspection dates, findings, and any corrective actions taken. This documentation can be valuable for tracking the condition of your brake system over time.

It's important to follow a regular maintenance schedule as recommended by the manufacturer or regulatory authorities. Additionally, air brake systems should be inspected by qualified technicians as part of routine vehicle or machinery maintenance. Properly maintained air brake chambers contribute to safer and more efficient braking operations.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语