The biggest issue with air disc brakes is their initial cost. They are generally about 30% - 40% more expensive to outfit a truck or trailer with than drum brakes. But over time, this increased upfront cost is offset by lower ongoing maintenance expenses.

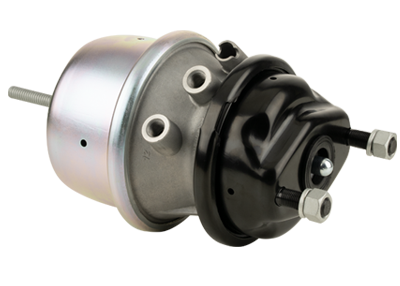

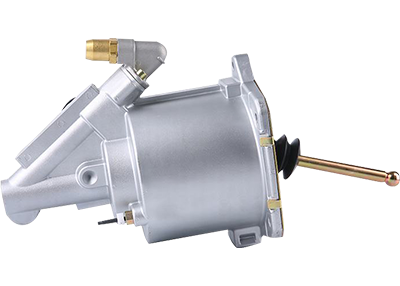

Unlike drum brakes, disc brakes use friction between pads and a metal disk known as a rotor to slow the wheel. The rotor is mounted inside of a brake carrier and is separated from the brake shoes by a bridge. When the brake is activated, a spring pushes the caliper across the brake carrier and engages the pads with the rotor. This generates heat, which reduces the stopping power of the wheels. The caliper is then returned to its rest position by a return spring.

Brake calipers and bridges are also susceptible to corrosion, which can cause the brakes to fail. This corrosion can lead to leaking of the brake fluid, which is responsible for braking pressure. This can also cause the brake pedal to become spongy or fail to engage when pressed. Fortunately, brake manufacturers make these components from stainless steel and they are available in a variety of options to reduce corrosion risk.

Aside from corrosion, another common maintenance issue is rotor wear. This is not uncommon on heavy vehicles in dusty environments. The abrasive environment can lead to high rates of rotor wear, which can result in premature replacement and increase the overall cost of ownership.

As a solution to this, brake makers have developed products to improve rotor life. Some of these products include rotor coatings to reduce abrasion, which can damage the rotor and contaminate the brake pads. Another popular product is pad wear sensing technology, which uses an air line to record a diagnostic trouble code when the brake pads are nearing their end of life. This helps fleets to proactively schedule maintenance and avoid damaging the more costly brake rotor.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语