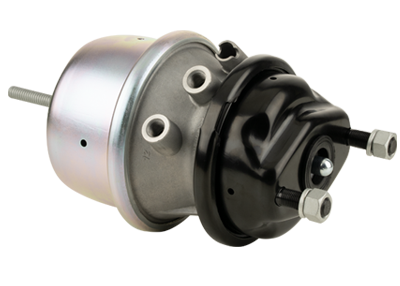

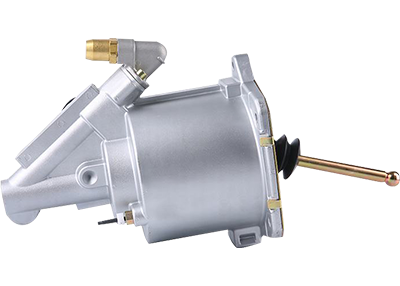

The key component in an air disc brake is the caliper which houses the brake pads. The caliper is attached to the brake carrier and contains a piston or two that, when air pressure is applied, generates amplified brake force through mechanical leverage. The resulting mechanical advantage is sufficient to squeeze the brake pads against the disc or rotor, slowing the wheel and applying the parking brake when the lever is released.

Air disc brakes offer a lower initial investment cost than drum brakes. This, combined with the benefits of increased braking efficiencies and shorter stopping distances has led many fleets to spec them as standard equipment on new trucks. In fact, according to brake manufacturer , a majority of major OEMs now make disc brakes standard on steer and drive axles.

Unlike drum brakes, the friction pads in air disc brakes are mounted on a rotating metal disc called a rotor. When a truck brakes the rotor is pressed against the brake pads by the caliper and this creates heat that transforms the kinetic energy of motion into thermal energy which causes the wheels to slow. The rotor is exposed to the outside air so it can cool quickly, which helps reduce fading and overheating. In addition, the rotor is smaller than a drum brake drum and this allows for more friction surface area allowing it to produce more braking power with a lower mass.

Brake pad wear sensing technology can help to further improve TCO by reducing maintenance time and costs. The sensor detects when the pads are nearing their end of life and alerts the technician without removing the brakes from the wheel. This helps to avoid overheating or fading by ensuring that the brakes are properly inspected and maintained.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语