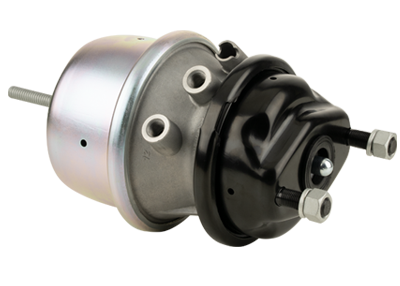

Air in the supply system is filtered, dried, compressed and stored in the main air reservoirs. The air pressure is kept at 130 to 140 psi. The air in the main air reservoirs is transferred to the auxiliary and emergency air reservoirs by a series of pneumatic control valves. Each car in the train is supplied with its own auxiliary air reservoir. The CCV, affixed to the brake pipe bracket, has 2 valve portions, Service and Emergency. It has 3 functions: to charge the auxiliary and emergency reservoirs from the brake pipe, to operate the braking system, and to release it.

The CCV is a complex valve assembly, but the essential function is to maintain air pressure at each vehicle during a braking application. This is called “brake pipe pressure maintaining.” It prevents the auxiliary and emergency reservoirs from draining faster than the brake pipe can recharge them. This problem is a frequent cause of train runaways. A simple way to avoid it is to not use the train brakes for long descending grades, and only to apply them once to the point where the air pressure in the brake pipe drops to zero psi.

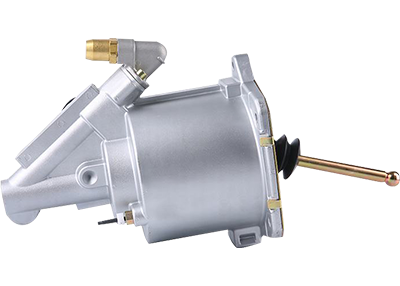

In traditional systems with a triple valve, the Lap position of the foot value dumps air from one side of the piston to the other. This is used in emergencies only, when the triple valve senses a sudden drop of air pressure along the brake pipe. Some triple valves and distributors are fitted with sensor valves that sense a rapid drop in air pressure. This increases the rate at which brakes are applied, but it cannot be relied on to initiate an emergency application.

An emergency reservoir is provided on each car and recharges from the brake pipe, but it is not activated until the emergency valve opens. Some trains are also equipped with a special version of the triple valve, called a distributor, which performs the same function but includes a graduated release capability that improves brake control. This is not used on modern air braking systems, which use a sensor-equipped air distribution control to achieve the same effect. The air distribution control is typically affixed to the end of the brake pipe, and has angle cocks that are closed when the vehicle is uncoupled.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语