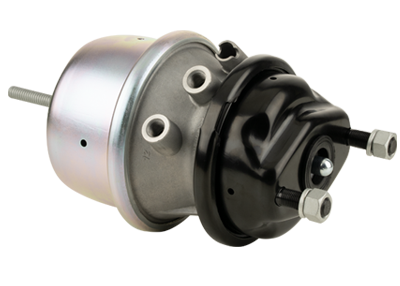

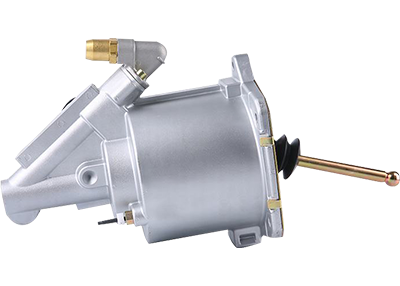

The parking/emergency brake chamber is a separate component that houses a large coil spring to hold the brakes in the off position, usually when the vehicle is parked and unattended . It is not serviceable and any attempt to open it could cause injury or death from the high spring force. The parking/emergency brake is typically a “piggy back” type that stores a caging bolt that is used to mechanically restrain the coil spring during servicing and replacement. The caging bolt is inserted into a hole in the piggy back section and then a washer and nut are threaded onto it to “cage” the spring and make it safe to remove and replace the brake chamber.

If the caging bolt is missing or damaged, it is important to note that the parking/emergency brake cannot be removed and may not be able to be safely towed. If this is the case, it is important to inspect and replace the caging bolt to ensure that the large spring can be re-caged before installing a new brake chamber.

Air Brake Chambers

There are many types of air brake chambers but most commercial vehicles use a clamp type that is held together by a pair of concave metal halves with a round rubber diaphragm sandwiched in between. A metal piston with a threaded end extends through a hole in one of the brake chamber halves and when air pressure from the brake line is applied to the brake pedal, the pushrod is extended to engage the brakes. When the brake pedal is released, a return spring returns the pushrod to its original position .

A brake chamber’s stroke is determined by the maximum displacement of its piston or diaphragm. During testing for compliance with NHTSA’s minimum vehicle reservoir capacity regulations, the stroke is measured by a pressure gauge while the brakes are activated. The test results are used to calculate the rated volume of each brake chamber based on the manufacturer’s design and full stroke displacement. The rated chamber volume must also account for the void ahead of the relaxed piston or diaphragm, which is known as the pre-fill stroke.

During an inspection of the air brake system, it is important to look for signs of damage or wear to the brake chambers such as corrosion on the power spring or pressure plate, dents in the body of the chamber and any indications that the pushrod may be worn or bent. It is recommended that new brake chambers be replaced with like-for-like units to avoid the possibility of a different pushrod stroke length causing short-term issues or longer term problems such as a decreased braking force or even pushrod failure.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语