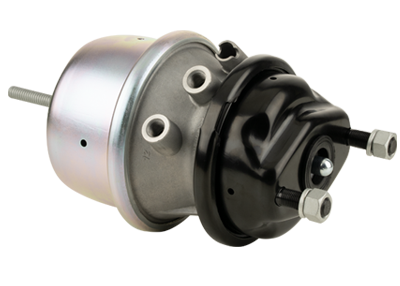

Mitigation principle

When the driver puts the brake valve in the relief position, the compressed air from the main air cylinder enters the main brake pipe, enters the three-way valve through the brake branch pipe, and pushes the active piston together with the slide valve to move to the right, opening the air filling ditch and allowing the compressed air to pass through The air filling groove enters the auxiliary air cylinder until the air pressure in the auxiliary air cylinder is equal to the pressure in the brake main pipe. When the main piston of the three-way valve moves, the slide valve connected with it also moves to the right, so that the compressed air in the brake cylinder is discharged through the exhaust port under the slide valve, so the brake cylinder piston is spring-loaded. The elastic force pushes back to the original position, so that the brake shoes are released from the wheel and relieved.

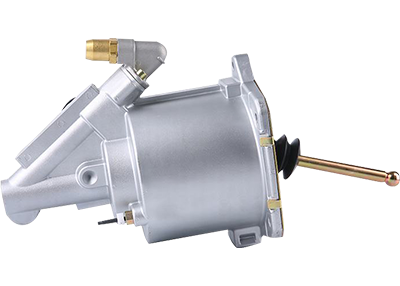

In order to adapt to the development of large-tonnage and high-speed vehicles, my country’s railways have mass-produced and installed new-type air brakes. In addition to adding a working air cylinder, the new-type air brake uses an air brake valve to replace the tee. Outside of the valve, the rest is basically the same as the above-mentioned air brake.

The new air brake has rapid braking action, high sensitivity, and strong braking force. It can shorten the braking distance during normal braking or emergency braking, which is beneficial to increase the running speed of the train; the braking force of the train before and after the train is relatively consistent; The brake is stable, the operation is convenient, and the driving safety is ensured; it is convenient for maintenance and other advantages. Vehicles equipped with new brakes can be combined with vehicles equipped with ordinary brakes.

Braking principle

When the driver moves the brake valve to the braking position, the compressed air in the brake pipe is discharged to brake.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语