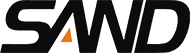

The materials used in a disc brake chamber can vary based on the manufacturer and the specific model. However, high-quality disc brake chambers are typically designed to be durable and resistant to corrosion, given their exposure to the elements. Here are some

considerations regarding the materials used in disc brake chambers:

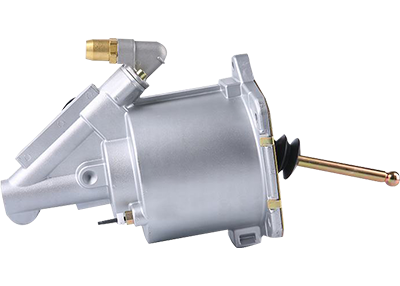

Aluminum Alloy:

Many disc brake chambers use aluminum alloy in their construction. Aluminum is lightweight, corrosion-resistant, and provides strength. The alloy is often treated or coated to enhance its durability and resistance to environmental factors.

Stainless Steel:

Some disc brake chambers may incorporate stainless steel components. Stainless steel is known for its excellent corrosion resistance, making it suitable for parts exposed to the elements.

Corrosion-Resistant Coatings:

In addition to the base materials, manufacturers may apply corrosion-resistant coatings or finishes to further protect the disc brake chamber. These coatings can enhance resistance to rust and other forms of corrosion.

Polymer Components:

Certain components within the disc brake chamber, such as seals and bushings, may be made of high-quality polymer materials. These materials can resist corrosion and provide durability.

Weather-Sealed Design:

Disc brake chambers designed for outdoor use often feature weather-sealed designs. Seals and gaskets help prevent moisture, dust, and other contaminants from entering the chamber, reducing the risk of corrosion.

Compliance with Standards:

Reliable disc brake chambers are often designed and manufactured to comply with industry standards and regulations. Meeting these standards may include using materials that withstand exposure to environmental conditions.

Manufacturer Specifications:

Review the manufacturer's specifications and product details to learn more about the materials used. Manufacturers typically provide information on the composition and protective measures taken to ensure durability.

User Reviews:

Reading user reviews can provide insights into how well the disc brake chamber holds up over time in real-world conditions. Users often share their experiences with durability and resistance to corrosion.

It's essential to consider the specific environmental conditions your vehicle will face, such as exposure to salt (common in winter climates), moisture, and varying temperatures.

Regular maintenance, including cleaning and inspection, can also contribute to the longevity of the disc brake chamber.Before making a purchase, consult the product documentation, manufacturer's pecifications, and user reviews to ensure that the disc brake chamber is constructed with materials that provide the necessary durability and corrosion resistance for your intended use.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语