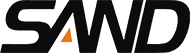

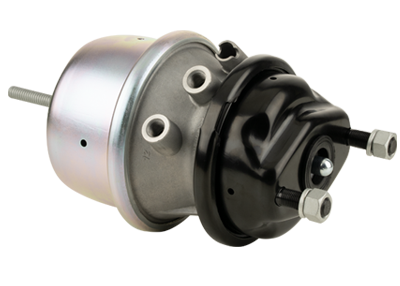

Spring brake cylinders in air brake systems require regular maintenance to ensure the safe and reliable operation of the braking system. Routine maintenance helps prevent issues, prolong the life of components, and ensures that the vehicle's brakes function as intended.

Here are some key aspects of regular maintenance for spring brake cylinders:

Visual Inspection: Conduct regular visual inspections of spring brake cylinders to check for signs of damage, corrosion, or leaks. Look for wet spots, air bubbles, or any other visible issues.

Lubrication: Periodically apply brake cylinder lubricant to ensure smooth operation of the cylinder's internal components and prevent premature wear and damage.

Air System Inspection: Inspect the entire air brake system, including hoses, valves, and connections, to check for leaks, damage, or improper operation. Ensure that the air system is free of contaminants.

Stroke Adjustment: Adjust the stroke of the spring brake cylinder as needed to maintain proper brake balance. Follow the manufacturer's recommendations for stroke adjustment.

Seal and Diaphragm Inspection: Check the seals and diaphragm for wear, damage, or signs of aging. Replace these components when necessary.

Replace Worn Parts: If you identify any worn or damaged components, such as seals, diaphragms, or springs, replace them with new, compatible parts.

Testing: Test the spring brake cylinder's ability to apply and release the spring brakes as needed. Ensure that it operates smoothly and effectively.

Air Pressure: Verify that the air pressure system is operating within the recommended pressure range. Low air pressure can affect the performance of the spring brake cylinder.

Brake Adjustment: Regularly check and adjust the brakes in the entire air brake system to maintain proper braking efficiency and compliance with regulatory requirements.

Winterization: In cold climates, take special care to protect the spring brake cylinder from freezing by using appropriate anti-freeze solutions and insulation.

Spring brake cylinders require regular maintenance to ensure they are functioning correctly and to prevent potential issues. The maintenance schedule for spring brake cylinders can vary depending on the manufacturer and the specific model of the cylinder. brake cylinder

should be removed from the brake rigging at least once every 144 months, or more frequently if service conditions require.

It is important to note that spring brake cylinders are under a mechanical load and pose a safety hazard to those servicing the cylinder. Therefore, it is recommended that you exercise care and follow proper safety protection procedures per your shop’s discretion .

If you are unsure about how often your spring brake cylinders should be serviced or if you are experiencing any issues with your braking system, it is best to consult with a qualified mechanic.

英语

英语 中文简体

中文简体 德语

德语 俄语

俄语 西班牙语

西班牙语 法语

法语